|

|

|

| Double Column Milling Center |

|

| Slant Bed CNC TEACH-IN Lathe |

|

| Turning Milling CNC Lathe |

|

| Gantry & Turret CNC Lathe |

|

|

|

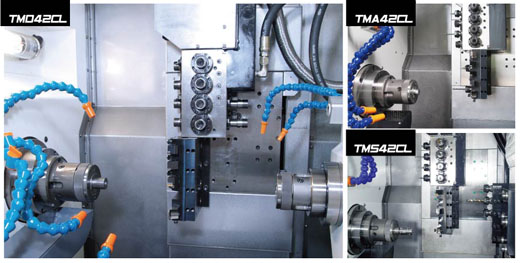

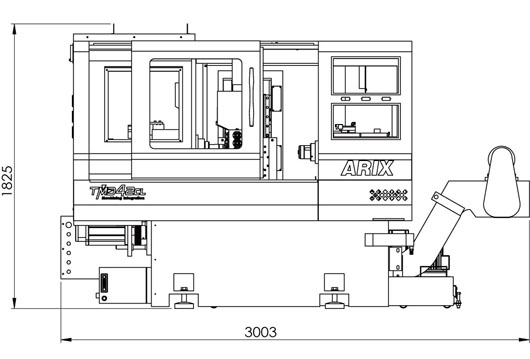

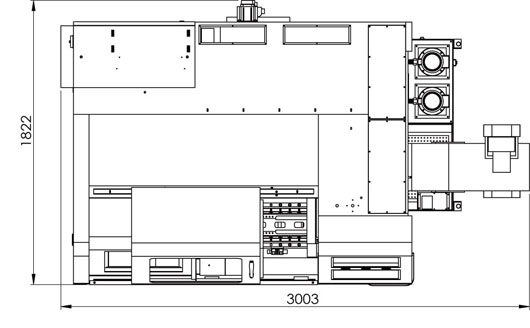

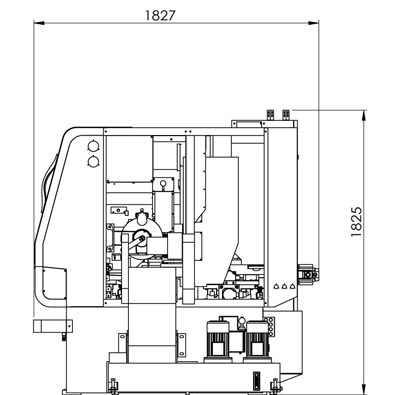

TM Series Turning Milling CNC Lathe TM Series Turning Milling CNC Lathe |

|

- Machine & technology

- Technology & Options

- Controls

- Specifications

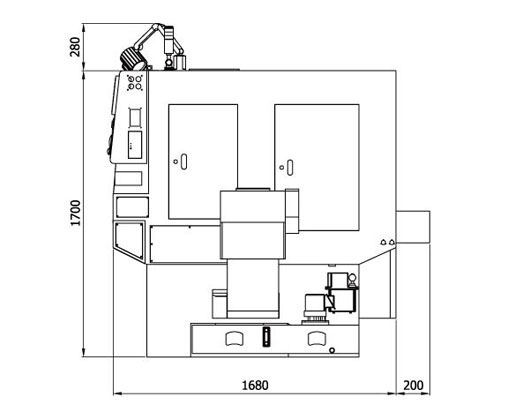

- Floor Plans

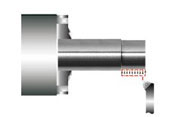

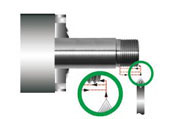

| Hydraulic Chuck |

|

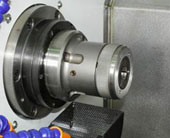

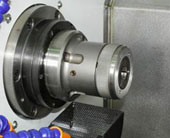

Precision Spindle |

|

8” Hydraulic Jaws Chuck

(For TM50/TMD50) |

|

|

|

|

|

| The standard hydraulic collect chuck controlled by a foot switch for efficient clamping. For the optional jaws chuck, inward or outward clamping can be set by parameters. |

|

The cartridge type is conveniently removed allowing for convenient servicing. The spindle runs on class P4 precision bearings providing high axial thrust capability. This ensures high precision during heavy duty turning. |

|

The optional jaws chuck controlled by a foot switch for efficient clamping. The inward or outward clamping can be set by parameters. |

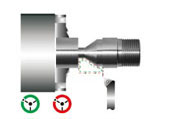

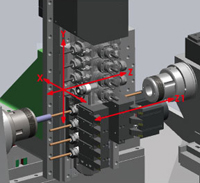

| Linear Life Tools Turret |

|

Spindle hydraulic brake |

|

Network / CF card reader |

|

|

|

|

|

| The turret provides quick tool change and reduces no-cutting time by linear transverse. The live tools are powerful enough to cut even stainless steel bar up to 42mm. |

|

The two steps hydraulic brake that can ensure the smooth C axis motion for machining in light braking force. The heavy braking can stop and take all the vibration from milling operations. |

|

ARIX CNC can provide a ball Bar Testing to replace actual circular cutting Test to adjust the relevant electrical parameters. |

| All axes are rigid linear guides |

|

Part Catcher |

|

Part Conveyor and Collector |

|

|

|

|

|

| The six blocks support gives the highest rigidity and accuracy among similar specifications machines. |

|

The standard part catcher makes the whole process more smoothly. |

|

The standard part conveyor gets the production fully automation. |

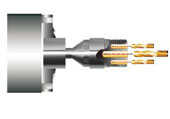

| Spindle motor |

|

Chip Conveyor |

|

Swiveling operating panel

with LCD display |

|

|

|

|

|

| The BBM motor can cover both low speed high torque C axis motion and high speed turning. |

|

The standard chip conveyor brings out all the chips efficiently and let the cutting area clean. |

|

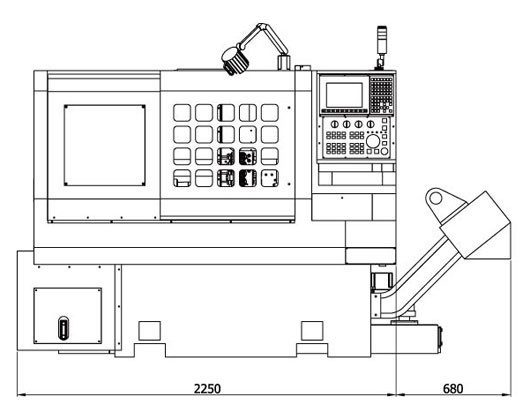

| Turning Milling Machine Specifications |

( ) is the optional items |

| Specifications |

UNIT |

TMA42CL |

TMS42CL |

TMD42CL |

TMA50CL |

TMD50CL |

Max.Turning Diameter

|

mm |

130 |

130 |

130 |

130 |

150 |

Max.Turning Length

|

mm |

160 |

160 |

160 |

160 |

300 |

Stroke of X

|

mm |

225 |

225 |

225 |

225 |

270 |

Stroke of Z

|

mm |

235 |

235 |

235 |

235 |

450 |

Stroke of Y

|

mm |

385 |

385 |

385 |

385 |

370 |

Stroke of X1

|

mm |

N/A |

460 |

N/A |

N/A |

N/A |

Stroke of Z1

|

mm |

N/A |

352 |

350 |

N/A |

460 |

Main Spindle Bore

|

mm |

42 |

42 |

42 |

50 |

50 |

Main Spindle Nose

|

|

A2-5 |

A2-5 |

A2-5 |

A2-6 |

A2-6 |

Main Spindle speed

|

r.p.m |

40-6,000 |

40-6,000 |

40-6,000 |

40-4,000 |

40-4,000 |

Main Spindle Power

|

Kw |

7.5 |

7.5 |

7.5 |

11 |

11 |

Sub Spindle Bore

|

mm |

N/A |

N/A |

30 |

N/A |

30 |

Sub Spindle Nose

|

|

N/A |

N/A |

A2-4 |

N/A |

A2-5 |

Sub Spindle speed

|

r.p.m |

N/A |

N/A |

40-3,000 |

N/A |

40-3,000 |

Sub Spindle Power

|

Kw |

N/A |

N/A |

3 |

N/A |

3 |

Number of fixed tools

|

|

5 Turning

+10 I.D |

5 Turning

+9 I.D |

8 Turning

+7 I.D |

5 Turning

+10 I.D |

8 Turning

+7 I.D |

Turning tool diameter

|

mm |

16 & 20 |

16 & 20 |

16 & 20 |

16 & 20 |

16 & 20 |

Boring tool diameter

|

mm |

25 |

25 |

25 |

25 |

25 |

Number of live tools

|

|

8 |

8 |

10 |

8 |

11 |

Power of live tools

|

Kw |

1 |

1 |

1 |

1 |

1 |

Tailstock

|

|

N/A |

5 I.D Tools |

N/A |

N/A |

N/A |

X axis servo motor

|

Kw |

1 |

1 |

1 |

1 |

1 |

Y axis servo motor

|

Kw |

1 |

1 |

1 |

1 |

1 |

Z axis servo motor

|

Kw |

1 |

1 |

1 |

1 |

1 |

X1 axis servo motor

|

Kw |

1 |

1 |

N/A |

1 |

N/A |

Z1 axis servo motor

|

Kw |

N/A |

500W |

1 |

N/A |

1 |

Rapid Transverse

|

M/min |

17 |

17 |

15 |

15 |

15 |

Coolant Tank Capacity

|

L |

40 |

40 |

40 |

40 |

15 |

Coolant Pump

|

HP |

1/2 |

1/2 |

1/2 |

1/2 |

1/2 |

Hydraulic Pump

|

HP |

1 |

1 |

1 |

1 |

1 |

Dimension

|

M |

2.5 x 1.9 x 1.8 |

2.5 x 1.9 x 1.8 |

3.0 x 2.1 x 1.8 |

2.5 x 1.9 x 1.8 |

2.5 x 2.5 x 1.9 |

| Machine Weight |

kgs |

3000Kgs |

3200Kgs |

3200Kgs |

3000Kgs |

3700Kgs |

| |

★ Design and specifications are subject to change without prior notice. |

| Standard

Accessories |

Optional

Accessories |

1.Operative Lamp

2.Tool Box

3.Tapping Shaft

4.Drilling Shaft

5.Automatic Lubricant System

6.Part Catcher

7.Chip Conveyor

8.Servo Motor 1000W

9.Side Milling 4PCS +

10.Front Side Milling 4 PCS |

1.Auto Bar Feeder Machine

2.Automatic Transformer & Stabilizer (15Kva) |

|

|