|

|

|

| Double Column Milling Center |

|

| Slant Bed CNC TEACH-IN Lathe |

|

| Turning Milling CNC Lathe |

|

|

|

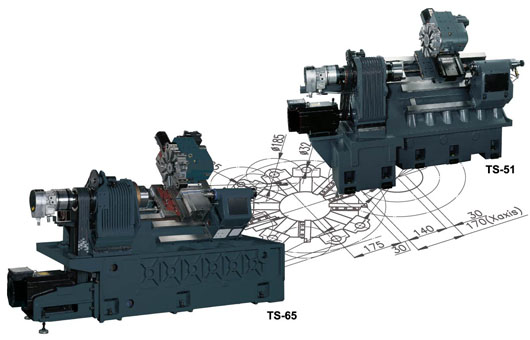

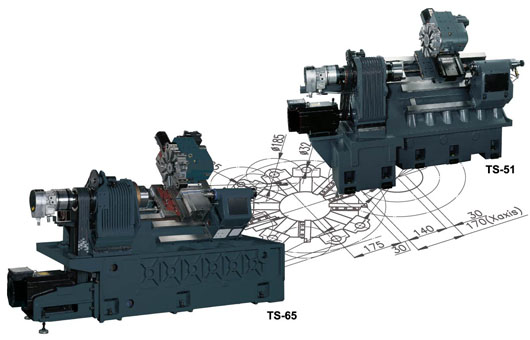

TS Series Slant Bed CNC TEACH-IN Lathe TS Series Slant Bed CNC TEACH-IN Lathe |

|

- Machine & technology

- Technology & Options

- Controls

- Specifications

- Floor Plans

The new slant bed CNC TEACH-IN lathe from ARIX

gives extraordinary machining capacity, stability and precision. |

The specially designed structure enhances the heavy cutting capabilities

and easy operation TEACH-IN controller makes the quick and simple setup

and programming.

|

Heavy duty Meehanite Cast Bed

The optimal structure is ribbed for maximum stiffness. The optimal structure is ribbed for maximum stiffness.

The gray cast iron offers excellent damping properties and Meehanite process ensures the casting is

properly heat treated and annealed before aging. The gray cast iron offers excellent damping properties and Meehanite process ensures the casting is

properly heat treated and annealed before aging.

The homogenized casting is free from any stress concentrations that can withstand any heavy-duty cutting. The homogenized casting is free from any stress concentrations that can withstand any heavy-duty cutting.

45°slant bed construction assures solid support of turret and efficient chip removal. 45°slant bed construction assures solid support of turret and efficient chip removal.

Hand Scrapped Box side ways

The Cast-in slide-ways generates the maximum rigidity. The Cast-in slide-ways generates the maximum rigidity.

The heat treatment by high frequency induction heating produces a depth of 0.5 mm maximum wear

resistance structure with tough internal core. The heat treatment by high frequency induction heating produces a depth of 0.5 mm maximum wear

resistance structure with tough internal core.

The precise & fine hand scrapping on all contact surfaces ensure the accuracies are held throughout

machine life. The precise & fine hand scrapping on all contact surfaces ensure the accuracies are held throughout

machine life.

|

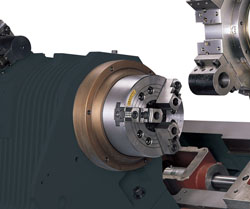

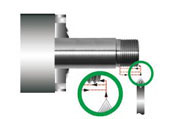

High rigidity, High Precision Spindle

The spindle is encased in the ribbed headstock for maximum heat dissipation. The spindle is encased in the ribbed headstock for maximum heat dissipation.

The thick cast iron case can damp all the vibration from cutting. The thick cast iron case can damp all the vibration from cutting.

For spindle configuration, the angular thrust bearings to absorb axial cutting forces and the roller

bearings with large bearing areas facilitate heavy cutting capacity. For spindle configuration, the angular thrust bearings to absorb axial cutting forces and the roller

bearings with large bearing areas facilitate heavy cutting capacity.

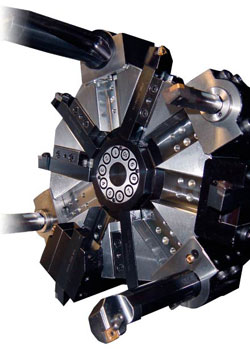

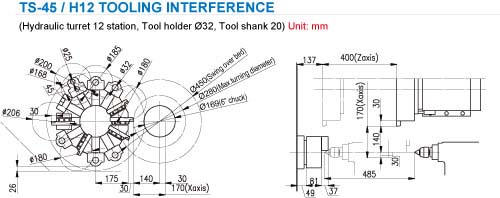

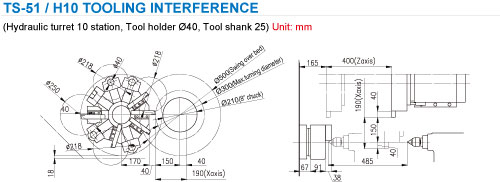

Fast indexing, durable turret

The turret has Curvic coupling for high positioning accuracy and the hydraulic clamping for heavy cutting. The turret has Curvic coupling for high positioning accuracy and the hydraulic clamping for heavy cutting.

The fast indexing with bi-directional random selection can shorten the setup time. The fast indexing with bi-directional random selection can shorten the setup time.

The hydraulic index motor offers optimum service life. The hydraulic index motor offers optimum service life.

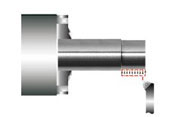

Programmable tailstock

The tailstock on slide way gives maximum clamping stability. The tailstock on slide way gives maximum clamping stability.

The smooth tow along action is done by turret. The smooth tow along action is done by turret.

The hydraulic clamping to bed has variable hydraulic pressure to tailstock quill. The hydraulic clamping to bed has variable hydraulic pressure to tailstock quill.

All tailstock movements are programmable bye M-code. All tailstock movements are programmable bye M-code.

Direct Drive Mechanism

High precision preloaded ballscrews for reduced backlash. High precision preloaded ballscrews for reduced backlash.

Direct coupling eliminates motor backlash and improves torque transmission characteristics. Direct coupling eliminates motor backlash and improves torque transmission characteristics.

Absence of belt or gear drives removes transmission vibration. Absence of belt or gear drives removes transmission vibration. |

| Quality Features Assure Greater Value! |

| RIGIDITY... STABLITY... PRECISION... |

|

|

|

| AUTOMATIC LUBRCATION SYSTEM |

|

LASTER INSPECTION |

The automatic lu-bricator provides lubrication toall slideways, ball screws and tail-stock ensures smooth motions atall times. The automatic lu-bricator provides lubrication toall slideways, ball screws and tail-stock ensures smooth motions atall times.

|

|

The CNC lathe has a standard hydraulic

chuck controlled by a foot switch for efficient

clamping of workpieces. The CNC lathe has a standard hydraulic

chuck controlled by a foot switch for efficient

clamping of workpieces. |

|

|

|

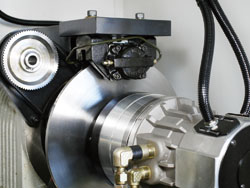

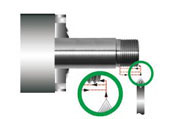

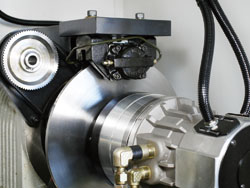

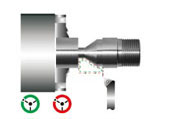

| SPINDLE HYDRAULIC BRAKE |

|

|

The two steps hydraulic brake that can ensure the smooth C axis motion for machining in light braking force. The heavy braking can stop and take all the vibration from milling operations. The two steps hydraulic brake that can ensure the smooth C axis motion for machining in light braking force. The heavy braking can stop and take all the vibration from milling operations.

|

|

|

|

|

|

| TOOL PRE-SETTER (option) |

|

CHIP CONVEYOR (option) |

The tool pre-setter effectively reduces

cutting tests while saving machining time. The tool pre-setter effectively reduces

cutting tests while saving machining time.

The mechanism is used for measuring the

tool diameter and length. The mechanism is used for measuring the

tool diameter and length.

The tool adjustment arm is powered and

program controlled. The tool adjustment arm is powered and

program controlled.

|

|

The chip conveyor can bring the chips away

from the working area to avoid the thermal

effect of chips. The chip conveyor can bring the chips away

from the working area to avoid the thermal

effect of chips.

It saves the time for clean up the chips and

can be controlled by program. |

|

|

|

COOLANT SYSTEM & OIL /

WATER SEPARATOR (option) |

|

PROGRAMMABLE TAILSTOCK (option) |

High capacity designed coolant tank maintains

the coolant temperature. High capacity designed coolant tank maintains

the coolant temperature.

The submerged type coolant pump delivers high

pressure coolant to flush chips and extend tool

service life. The submerged type coolant pump delivers high

pressure coolant to flush chips and extend tool

service life.

High efficient disk type oil / water separator

provides quick oil / water separate (option). High efficient disk type oil / water separator

provides quick oil / water separate (option). |

|

The ruggedly constructed, programmable

tailstock and quill movement can be

controlled on the control panel for easy

set-up and accurate positioning. The ruggedly constructed, programmable

tailstock and quill movement can be

controlled on the control panel for easy

set-up and accurate positioning.

Tailstock movement is driven by turret slide. Tailstock movement is driven by turret slide. |

|

|

|

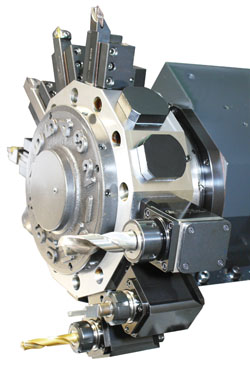

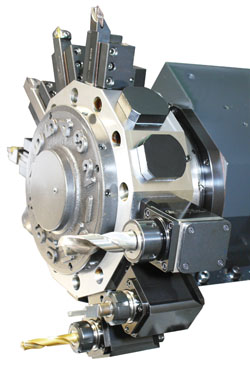

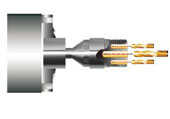

| TURRETS |

|

|

VDI30, 12-Position power turret with AC servomotor. VDI30, 12-Position power turret with AC servomotor.

Tool drive with spindle orientation. Tool drive with spindle orientation.

Tools individually driven. Tools individually driven.

Radial tool mounting. Radial tool mounting.

|

|

|

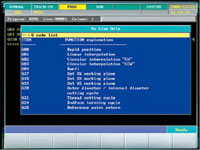

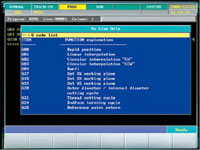

| Easy Progmminng Teach-In Functions |

|

|

|

|

|

TURNING

(STRAIGHT AND TAPER) |

|

FACING

(STRAIGHT AND TAPER) |

|

THREADING

(STRAIGHT, TAPER AND MULTIPLE) |

| Input the profile data from the blueprint. Press the simulation key to generate the graphic tool path. |

|

Input the specific parameters for this operation according to the graphic guide. |

|

For straight, taper or facial type of threads can be multiple as well. |

|

|

| On-line help let the operator do programming

without any NC background. |

|

|

|

|

|

| MPG SIMULATION |

|

END DRILLING |

|

GROOVING

(LONGITTUDINAL AND AXIAL) |

| After the machining program is loaded, select the MPG mode to let the NC program be executed according to the MPG rotaion speed. |

|

Input the start, end point and drilling conditions to generate the NC program. |

|

Do both longitudinal and axial grooving combining roughing and finishing. |

| TS Series Specifications |

( ) is the optional items |

| |

Update, please look forward to. Update, please look forward to. |

|

|

|