|

|||||||||||||||||||||||||||||||||||||||

|

- Machine & technology

- Technology & Options

- Specifications

- Floor Plans

| The New V series High Speed Centers. Completely Reinvented. |

| VMC5K Powerful machine covers wider rang cutting |

|

|

|

| . |

| Network/ CF card reader | ||

|

|

|

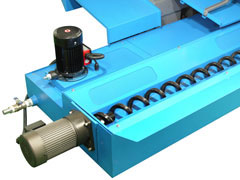

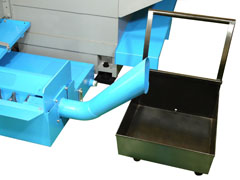

| Chip Conveyor | Chip Conveyor | |

|

|

|

| The chip conveyor can bring the chips away from the working area to avoid the thermal effect of chips. | It saves the time for clean up the chips and can be controlled by program. |

|

|

|

| VMC5K Specifications | ( ) is the optional items |

| Table | X axis | 5000 mm |

| Y axis | 300mm | |

| Z axis | 300mm | |

| Nose to table | 200~500mm | |

| Rapid | X / Y / Z | 20/20/20M/min |

| Max Feed | X / Y / Z | 20/20/20M/min |

| Table | Working surface | 1400*455mm |

| Load Capacity | 150kg | |

| Height of table | 700mm | |

| ATC | ATC type | Armless |

| Tool number | 16 | |

| Coolant System | Pump power | 1 1/2 HP |

| Tank capacity | L | |

| Spindle | Max Speed | 12000 RPM |

| Taper | BT 30 | |

| Motor | 5.5KW | |

| Cooling way | Oil cooler | |

| Tool | Max. tool length | 80 mm |

| Max. tool weigth | 8 kg | |

| Motor | Motor of tool magazine | 100 W |

| X, Y & Z servomotors | 2 KW | |

| Other | ||

| Air pressure | 5~7 kgf/cm2 | |

| Machine | Packing ( L x W x H ) | x x (cm) |

| Net weight | KGS | |

| Gross Weight | KGS |

| ★ Design and specifications are subject to change without prior notice. |

| Standard Accessories | Optional Accessories |

| 1. Coolant tank 2. Work lamp 3. Toolbox 4. Coolant motor 5. Coolant system 6. Spindle air blow system 7. Chip air blow device 8. Heat exchanger for cabinet 9. M30 Indication lamp 10. Full enclosed guard 11. Central lubricator 12. Manuals 13. Leveling bolts and pads 14. Armless ATC |

1. Ethernet 2. 2.1GHard desk 3. 4th axis 4. 5th axis 5. Tool setter 6. Optical scale 7. Dustproof device for graphite machining 8. Oil and lubricant separator 9. Oil-mist cooling system 10. Coolant through spindle 11. Thermal compensation of spindle expansion 12. Siemens controller |